Measuring machines - measuring devices

Basically, parts are measured to determine whether the geometric properties such as dimensions, shape and position tolerances correspond to the drawing specifications.

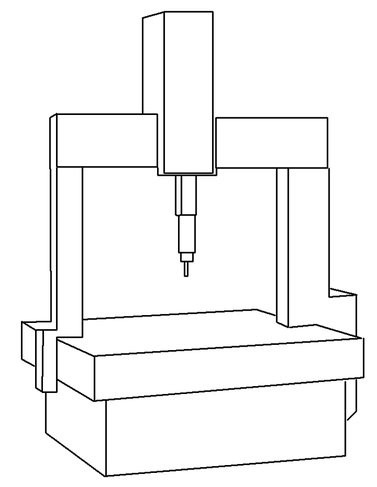

The CNC-controlled measuring devices significantly reduce the operator's influence on the measuring result and enable precise and repeatable measuring results.

A coordinate measuring machine (CMM) basically works just like our finger when we follow the coordinates on the map. Instead of a finger, however, the CMM uses a sensor to measure points on a workpiece (or why not on a guitar?).

Each point on the workpiece only exists once in the coordinate system of the measuring device. The CMM combines the measurement points to create a detail that can be related to all other elements.

From the operator's position in front of the machine, the X-axis runs from left to right, the Y-axis from front to back and the Z-axis perpendicular to the other two from bottom to top.

For guitar measurements, it would be better to swap the X and Y axes, which shouldn't be a big problem.

The touch finger has a smooth ball at the end. Surface damage, paintwork and the like can be completely ruled out with an optical sensor instead of a touch finger.

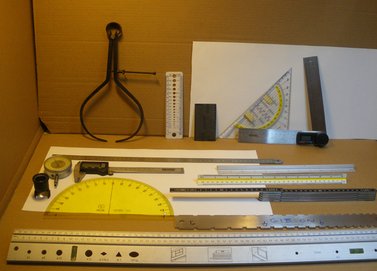

For now, let's leave complex measuring instruments and machines aside and look at commonly available tools for manual measurement.

We measure the guitar in a coordinate grid to determine the distance of the selected point from the zero point or from one element to another.

In order to measure these distances with an accuracy of ± 1 mm, the rulers, set square, etc. that we usually use for technical drawing are sufficient.

Nowadays, a digital caliper is well suited for finer accuracy.

We can achieve even finer measuring accuracy with a dial gauge (analog or digital), but for this we also need suitable devices.

A magnifying glass with lighting is also a very useful aid when it comes to reading fractions of a millimeter.

Inch or millimeter?

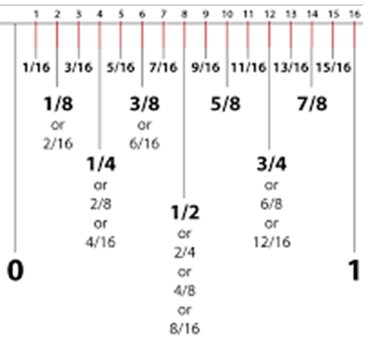

As a Central European I didn't have to bother with feet, thumbs, ells, etc. in school. Later, while building my own guitar, I found these archaic fractions in guitar specs kind of nice. Like a spice from Orient or Latin in the Catholic liturgy. "Metric is great for auto mechanics and science work, but it's not good for carpentry and cooking". Some Americans are also not satisfied with the tradition: "Metric is a superior system compared to imperial". But another proudly replies: "American made guitars are in inches." With all due respect to the fractional division of the inch, I cannot get along in the Cartesian coordinate system without millimeters and decimal meter fractions.

Nevertheless, the "Conversion Chart" conversion table has columns:

FRACTION OF INCH --- DECIMAL --- MILLIMETER

is my most important resource when researching guitar specs.

Optical measuring equipment

Photos of the guitar directly below the grid and with sufficient camera distance, almost perfectly prevents distortion of the proportions through perspective.

So that the lattice threads have sufficient contrast to all possible colors of the different guitars, the threads must have alternating black and white sections.

Smaller parts of the guitar such as the headstock, pickguard and f-cutouts are photographed under a certain grid of a matt transparent film.

The grid then serves as a ruler with a distance of 10 mm or 5 mm according to the points in between.

The exact alignment to the X axis, which should be in the middle between the D and G string contracts, as well as at the beginning of the scale length (front edge of the saddle), is done with the same 1: 1 arrangement.

Comments (0)

No comments found!