My Activities

String instrument measurement, dimensional analysis, developing hybrids

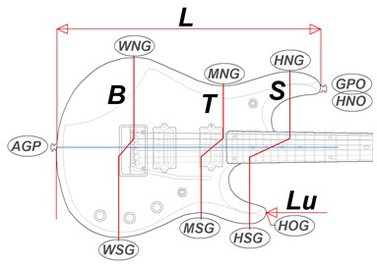

My target is to propose a precisely defined guitar measurement system with which all the most important specifications can be passed on without misunderstandings and with simple means. A dimensional Esperanto, so to speak. Suitable as a preliminary stage for CAD / CNC, but also for utensils such as pencil, ruler, compass, etc.

Because I come from a career in chemistry, dealing with graphics is a great challenge for me,

Although I don't like the slavish copying of guitars, I think it is not a sin to have one or more homemade guitars made as a copy of a tried and tested model. Of course with a lot of variety in details and above all with its own logo and not the same with the logo of the well-known manufacturer.

There are more and more plans, drawings and assets on the web, but no one knows where they are, intentionally or unintentionally, inaccurate.

For this reason, I download several variants of the drawing of the same type of guitar for each project in order to carefully trace and check them in order to make it my own (almost) reliable drawing.

Twelve-string Alto Model

I wanted a Chapman Stick many years ago. Unfortunately, at its price, it was practically prohibitive. Without thinking too much, I started with the "replica". But the maple blank had to wait a good 30 years for the continuation. The biggest problem was incomplete information, but unfortunately also my poor knowledge of English.

The decisive kick to keep going was the Chapmans SG12 stick in its bamboo version. Finally a concept for me, a guitar rather than a bass. Compared to building an electric guitar, it seemed like a much easier proposition. There is no body and the whole instrument is actually "just" a wide neck with a simple head on top. But appearances are deceptive, the path was accompanied by many "AHAs".

"Tapper EXP"

A twelve string musical instrument. EXP means experiment. Function is more important than appearance. And secondly, it should cost as little as possible, so every conceivable waste is recycled. A piece of multiplex residue 930 x 95 x 18 mm seemed suitable for the tapper neck. The small headstock and mini body were glued with epoxy:

Two aluminum "L" profiles, directly in contact with the frets, should be responsible for a "metallic" sound. An adjustable truss rod is of course also provided.

I use 2mm Ø stainless bicycle spokes as frets, which are preformed.

The frets are fixed with epoxy and the fingerboard is veneered piece by piece. Everything glued with epoxy, the veneer surfaces are also later laminated with epoxy.