About me

![[Translate to English:] Jan Jirasko](/fileadmin/assets/Content/Home/Ueber_mich/JJ-portret-2016.jpg)

I was born in Bystre (CZ) in July 1945 and grew up in northern Bohemia as the middle of three siblings. Until the mid-80s I worked as an electroplating technician and part-time as a musician in what was then Czechoslovakia. My other activities as a 30-year-old included self-building electric guitars and organs. Also house building, car repairs, wood processing, garden design and child rearing. At the age of 39, I moved with my family to Germany and got a position in research and development at an automotive supplier company in Stuttgart. In my retirement I devoted my professional experience fully to the construction of the electric guitar and related instruments.

My Home Made Guitars

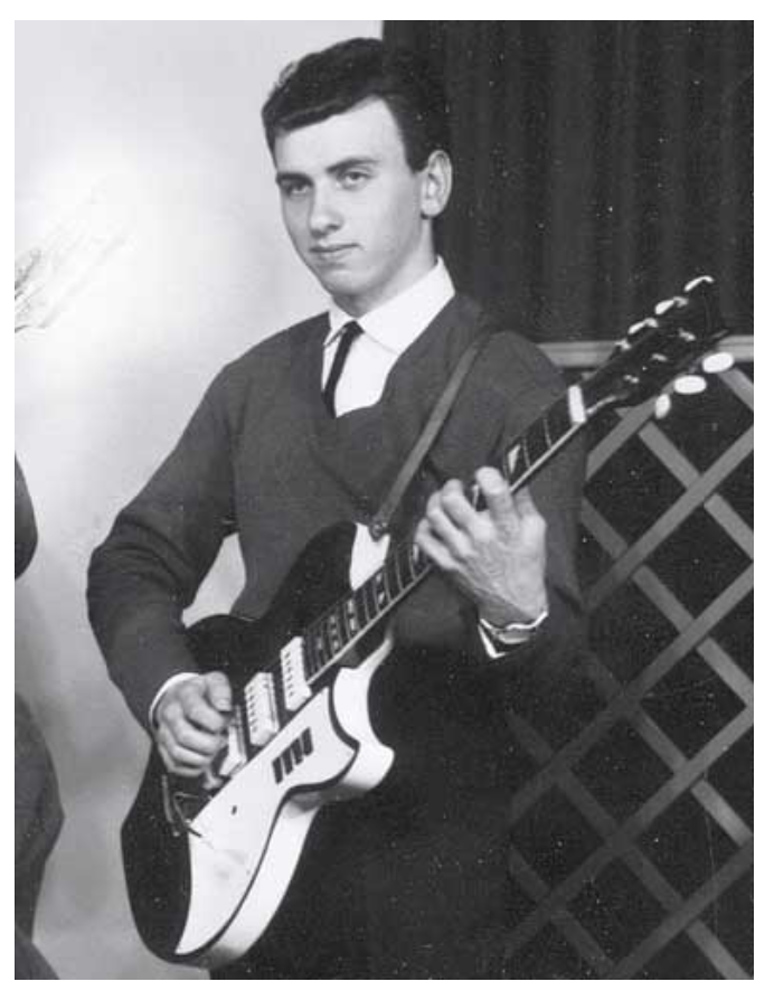

Home made 001a

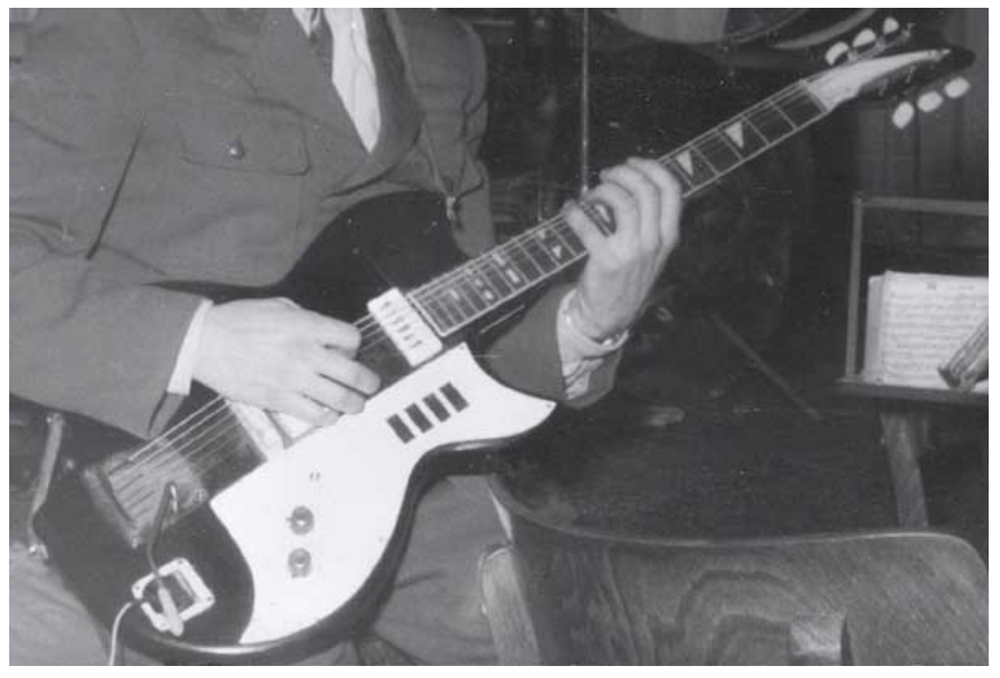

Home made 001b

Later I found the middle pickup unnecessary and the body got softer rounded edges and the headstock something of the Beatles and their Rickys. Two potentiometers, four changeover switches, but always only the flat cable socket with a flat plug, lag behind technical progress. The tremolo is self-made and of course self-chrome-plated with pre-copper and nickel plating and polished to a high gloss.

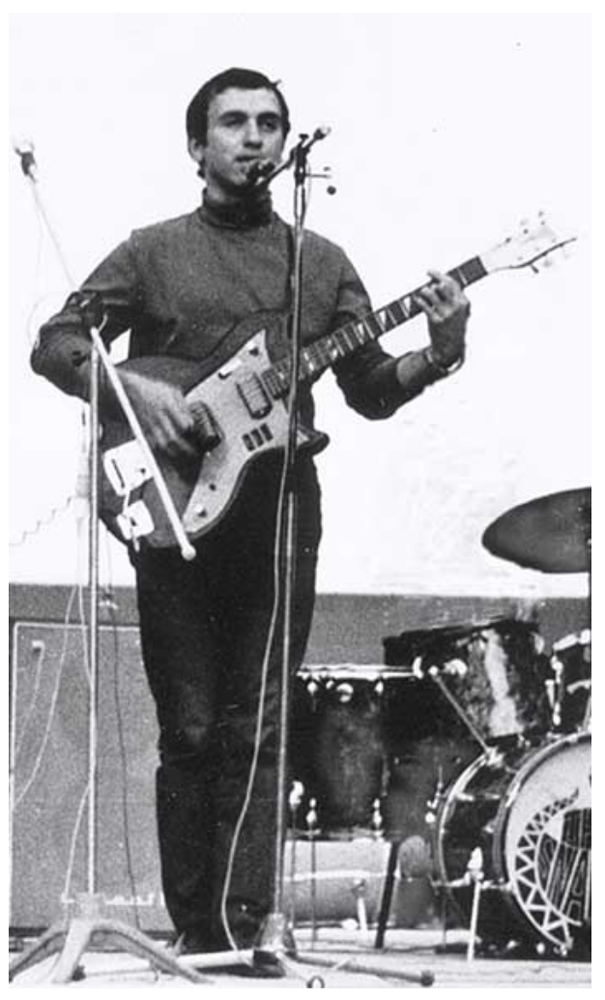

Home made 001c

Home made 003

Mid-1970s, and I "organized" two Ibanez humbuckers with potentiometers and toggleswitch. By chance I was given a piece of old larch wood for the body and maple for the neck was also there. I did all the woodwork with a hand saw, chisel, rasp and hand drill. It was quick and fun. Just no jumbo frets far and wide. So, filed a semicircle from 3 mm brass wire and then glued it at the fingerboard with epoxy. Scale length 630 mm Yes, the bridge and the tailpiece were of course forged and chrome-plated myself in the industrial electroplating shop I supervised. But I had the wooden surfaces painted by a professional with 2-component epoxy paint. I finally had a brand new guitar and almost 3 pounds less to carry! Playing comfort top notch!

Maturation process

At the turn of the 1970s and 1980s, I was concerned with the use of local wood (alder, poplar, maple, birch) for later building guitars. I had a large circular saw with a 10 kW motor with a feed on 5 meters of rails. I stored the cut wood to dry for several years. To be able to produce and experiment I bought several Strato kits, wound up the pickups too, and tried to design the hardware. At this point I have completed a total of 5 guitars and prepared to build an instrument similar to the Chapman's Stick. Before I moved to the Federal Republic of Germany in 1985, I sold or distributed almost all tools and materials to friends.

Active again

Home made TP 1

My special interest is the Chapman Stick and similar multi-string instruments. Compared to building an electric guitar, it seems much easier. There is no body and the whole instrument is actually "just" a wide neck with a simple head on top. But the appearance is misleading, the road was paved with many surprises.

Home made 007

The guitar was originally supposed to have the body and neck made of mahogany, and the rosewood fingerboard to go with it. Whether the ecologically sustainable raw material bamboo also has a significantly longer sustain is secondary to me. The body shape and details were designed by my wife after we disagreed on whether an Original SG is beautiful or not. Scale length 629 mm, hardware standard, chrome, PAF pickups.

The full bamboo neck has a "C" profile and the fingerboard a radius, 12 "at the saddle and 14" at the end. Everything done by hand, only with a chisel, scraper and sandpaper (with shaped washers). Yes, everything goes slowly, but I'm a multitasker, and on the side I work on a dozen ideas and have fun with them. That is the dilemma between creativity and productivity.

Home made 008

While cutting bread, the idea of "tomography" a guitar body came to mind. The drawing of the whole and the individual layers was completed quickly. So I bought spruce slats, Ponal glue and got to work. I drilled the inner outline of the future cavities and smoothed them out with a wood chisel and sandpaper. Little by little I glued everything together and and then I rounded the contours and sanded the surfaces smooth (by hand).

The next step was building the neck for nylon strings. The project is currently waiting for the bridge with a piezo pickup, the fretting, etc.

![[Translate to English:] Meine selbstgebaute E-Gitarre Nr. 7. Jahr 1978](/fileadmin/assets/Content/Home/Ueber_mich/SB7-JJ_120502.jpg)

![[Translate to English:] Mein selbstgebautes Tapping-Instrument 20177](/fileadmin/_processed_/9/a/csm_J_Yickist_2476_488edd4837.jpg)